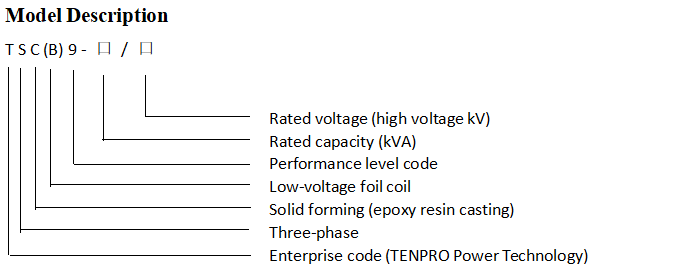

TSC9 Dry-type transformer

Product characteristics

Resin insulated dry transformer is our company imported foreign advanced technology, independently developed TSC9,TSCB9 series and TSC10,TSCB10 series thin insulation dry transformer with packing. Because the coil is sealed by oxygen resin, it is difficult to burn, fire proof, explosion-proof and maintenance-free,no pollution, small size, can be directly installed in the load center. At the same time, scientific and reasonable design and pouring process make the product have low partial discharge, low noise, strong heat dissipation ability, can run under 140% rated load for a long time under forced air cooling condition, and equipped with intelligent temperature control instrument, with fault alarm, Over temperature alarm, over temperature tripping and black box function, and through the RS485 serial interface and computer connected, can monitor and control centrally.

Due to the above characteristics of dry type transformers in our company, they are widely used in power transmission and transformation systems, such as hotels, airports, high-rise buildings, commercial centers, residential areas and other important places, as well as subway, smelting power plants, ships, offshore drilling platforms and other harsh environment.

Iron core

The iron core is made of imported high quality cold rolled silicon steel sheet, the structure of all oblique joint is adopted, the core column is bound by F class non-Wei adhesive band, and the iron core surface is encapsulated with epoxy resin, which reduces the no-load loss, no-load current and core noise. Clip and fastening through special surface treatment, the product appearance quality has been further improved.

High voltage winding

Vacuum pouring with filler epoxy resin for high voltage winding greatly reduces the partial discharge and improves the electrical strength of the coil. The inner and outer walls of the winding are filled with fiberglass mesh plate and the mechanical strength of the wire girth is enhanced. Improve the product’s ability to resist sudden short circuit, the coil will never crack.

Low tension winding

The low-pressure winding adopts foil structure, which solves the problem of axial helical angle when winding, and makes the casket more balanced. Meanwhile, the coil adopts axial cooling air duct, which enhances the heat dissipation ability. DMD epoxy resin preprepreg is used in the winding layers, the whole solidification forming.

Temperature control system and air cooling system

The cross flow top blow cooling fan is adopted. The cooling fan has the characteristics of low noise, high wind pressure and beautiful appearance. It enhances the overload capacity of the transformer, and adopts the intelligent temperature control instrument to improve the safety and reliability of the transformer operation.